Laboratories and departments

Laboratory 04 «Nanomaterials and Nanotechnologies»

-

Development and progress of methods for obtaining bulk nanostructured materials

-

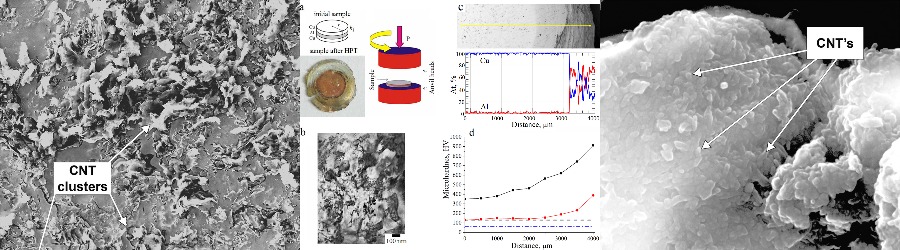

Development of methods for obtaining metal-matrix composites based on severe plastic deformation under pressure of layered components and their subsequent annealing.

-

Investigation of bulk configurations of graphene subjected to severe plastic deformation for the transport and storage of hydrogen, and the production of metal-carbon composites.

-

Emission properties of nanostructured materials obtained by deformation methods.

Laboratory 07 «Materials science of hard-to-form alloys»

-

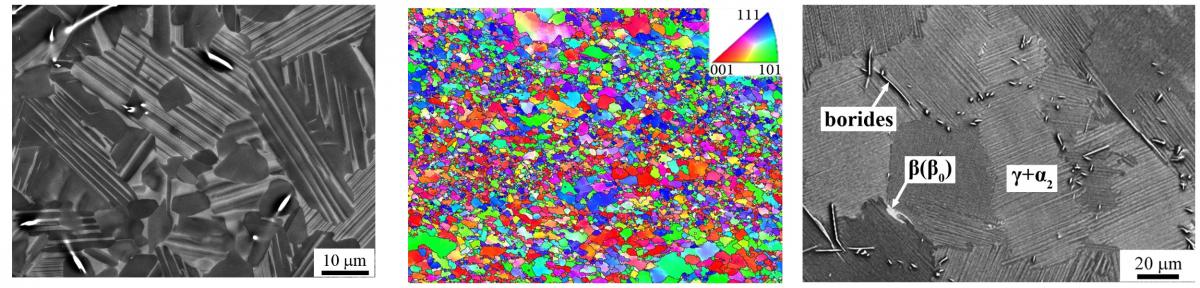

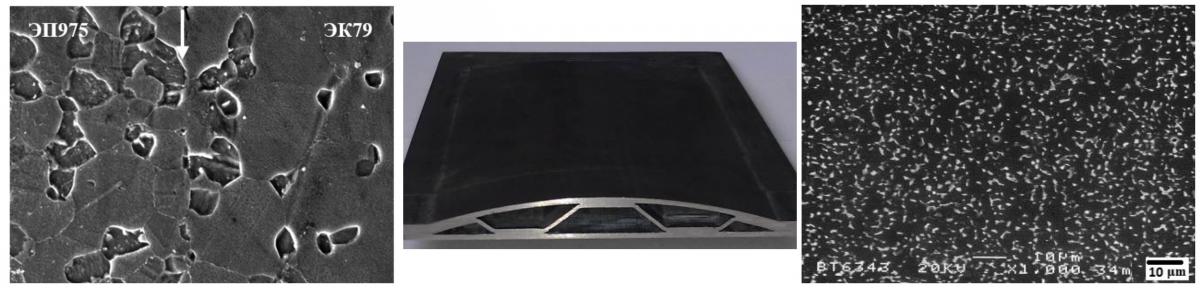

Development of light heat-resistant intermetallic alloys based on titanium aluminides and creation of the foundations of technologies for their shaping for the manufacture of complex-profile parts intended for use in aircraft engine building.

-

Development of the foundations of shaping technologies and equipment for the manufacture of axisymmetric critical products from high-temperature alloys and steels for use in aircraft / engine construction.

-

Development of composite materials and high-alloy titanium-based alloys, as well as methods for their processing, providing an increase in mechanical properties

Laboratory 08 «Materials science and technology of light alloys»

-

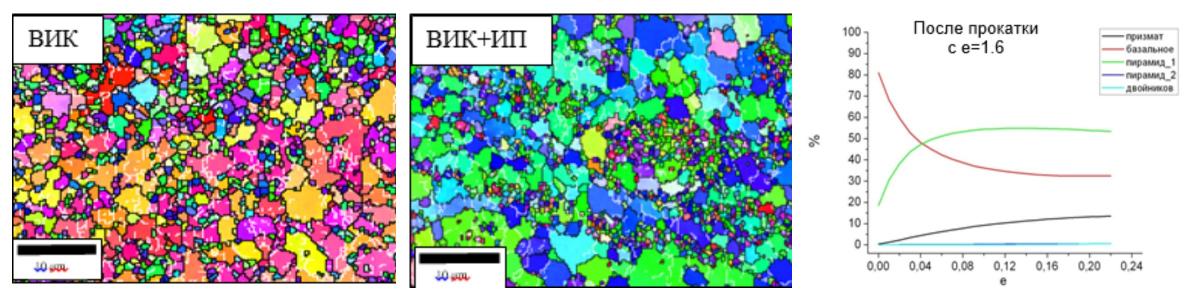

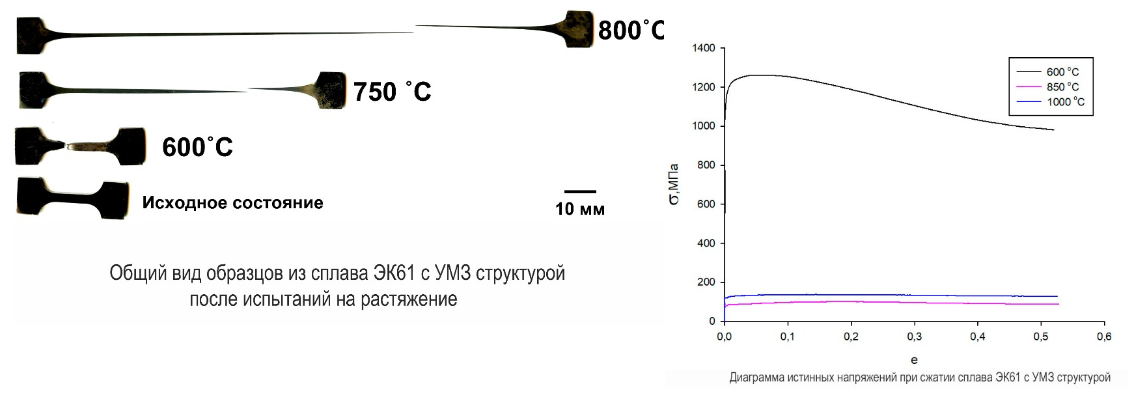

Research on the mechanisms and kinetics of dynamic recrystallization, mechanisms and phenomenology of superplastic deformation in aluminum and magnesium alloys, the development of various deformation-thermal methods of grinding their microstructure are being carried out.

-

The main attention is focused on the production of UFG and nanostructured light alloys, the study of their physical and mechanical properties, the development of the foundations of technological processes for superplastic forming and forging of complex-shaped products with a regulated structure and a set of properties.

Laboratory 09 «Nonlinear physics and material mechanics»

-

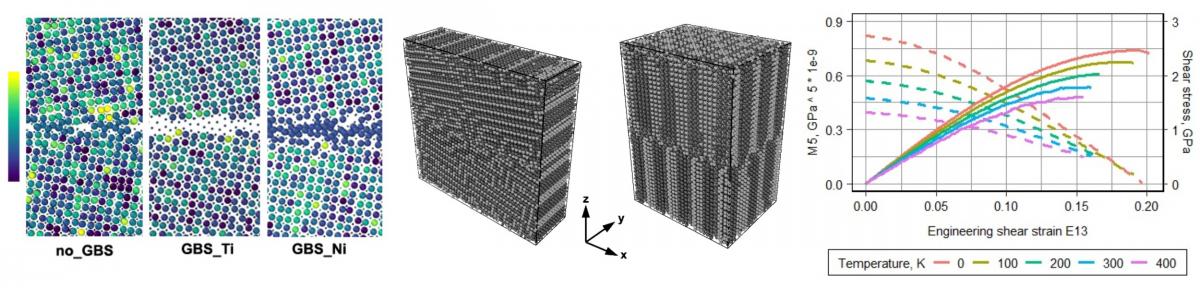

Molecular dynamic modeling of the structure of grain boundaries in ultrafine-grained materials, their interaction with dislocations, segregation of impurity atoms, response to various external influences (deformation, annealing, etc.).

-

Simulation of structural changes in nanostructured metals during ultrasonic treatment by methods of dislocation and molecular dynamics.

-

Study of nonlinear localized vibrational modes in crystals.

Laboratory 10 «Superplastic machining of promising materials»

-

Physical and computational modeling of the formation of crystalline materials using the effect of traditional and low-temperature superplasticity (SP) in the manufacture of light and durable structures.

-

Investigations of the material quality of hollow structures obtained by superplastic processing, including physical, mechanical and operational properties, using traditional and non-destructive diagnostic methods.

-

Study of the nature of the formation of a solid-phase joint during pressure welding of homogeneous and dissimilar crystalline materials using traditional and low-temperature SP.

Laboratory 11 «Physics and Mechanics of Carbon Nanomaterials»

-

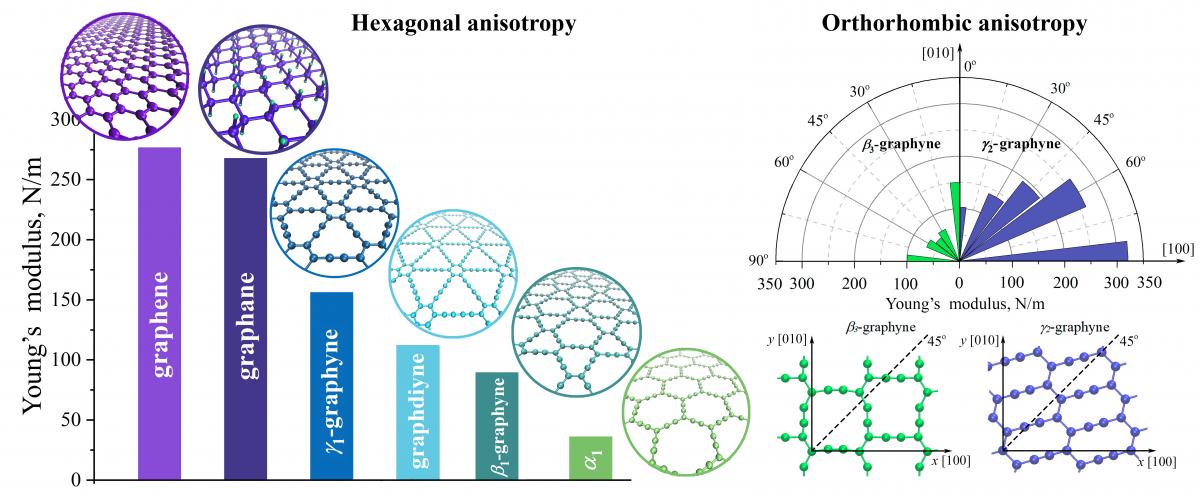

Modeling the structure of carbon nanomaterials (graphene, nanotubes, fullerenes, bulk materials based on them and their modification under elastic deformation.

-

Molecular dynamics simulation of the stability of new carbon nanomaterials.

-

Study of the mechanical properties and deformation behavior of carbon nanomaterials by molecular dynamics.

-

Study of the defect structure and dynamics of defects in carbon structures.

Innovation center

The innovation center includes five sectors: foundry, design and technology, isothermal stamping, rolling, and mechanical processing. The IMSP RAS Innovation Center is equipped with a modern fleet of equipment ( metalworking, deformation-technical processing of materials). Due to this, the IASM RAS can manufacture products and prototypes by orders of the research and innovation departments of the Institute, as well as outside organizations.

Promising developments

The sector develops pilot technological processes of hot die forging of complex-shaped parts made of aluminum, magnesium, titanium, heat-resistant and other alloys; designs and manufactures the necessary die tooling; on hydraulic presses with an effort of 100 to 1500 tons, it manufactures pilot and pilot-industrial batches of parts for aircraft building, engine building and other enterprises. The sector has extensive experience in the manufacture of pistons for engines of sports cars and trucks, sea and river vessels, special-purpose equipment; wheels made of aluminum alloys with a diameter of 12 to 22.5 inches with an increased level of mechanical properties; cylinders from high pressure aluminum alloys.

Optical metallography

The laboratory of optical microscopy solves the problems of qualitative and quantitative 2D / 3D analysis of the microstructure of various materials on optical and laser systems manufactured by Carl Zeiss and others. It has an Axiotech microscope, which allows digital registration of the image and using the image analysis program KS- 300 determine the linear dimensions of structural components (grains, phases, pores, cracks), build histograms of grain size distribution, determine the volume fraction of phases, etc. The laboratory has a photomicroscope "Neophot-32", which allows observations in dark and bright fields, polarization and DIC contrasts. The laboratory is equipped with an Axiovert-100A microscope with an MHT-10 attachment for measuring Vickers microhardness in thin samples and coatings.

Mechanical test group

The group of mechanical tests is equipped with universal electromechanical machines with a force of 100 kN: Instron 1185, Schenck Trebel RMC100, 1958-U10-1; Schenck Hydropuls PSA electro-hydraulic machine with a force of 100 kN; a machine for testing metals for creep and long-term strength 2147 P-30/1000 and a Schenck Trebel RPSW 150/300. This equipment makes it possible to conduct research at a high scientific and methodological level under various types of loading at room and elevated temperatures.

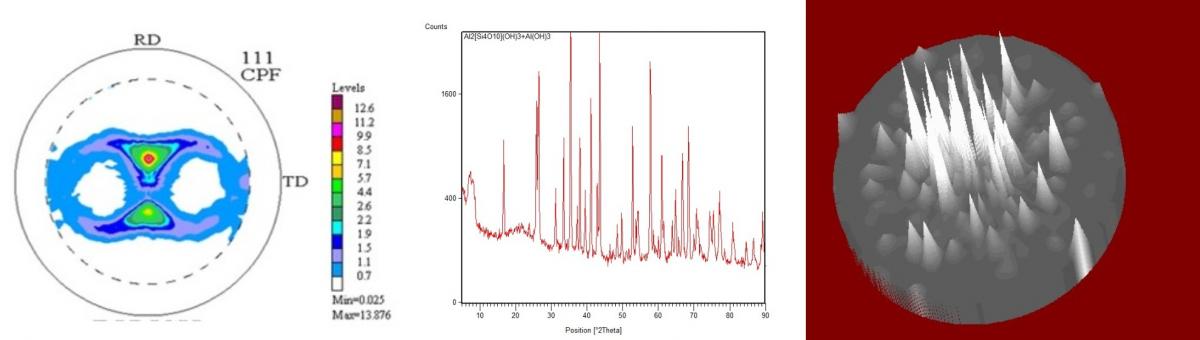

X-ray structural analysis group

The group of X-ray structural analysis solves the problems of qualitative and quantitative phase analysis of metallic materials, precision determination of the crystal lattice parameters, determination of the parameters of the fine structure of polycrystals (the average size of coherent scattering regions and rms relative microstrain), measurement of the texture of materials by the method of constructing inverse and direct pole figures. The laboratory is equipped with a general-purpose X-ray diffractometer: DRON-4 with an automated attachment for recording straight pole figures, DRON-4-07 with hardware and software complexes for controlling the diffractometer and recording measurement results.

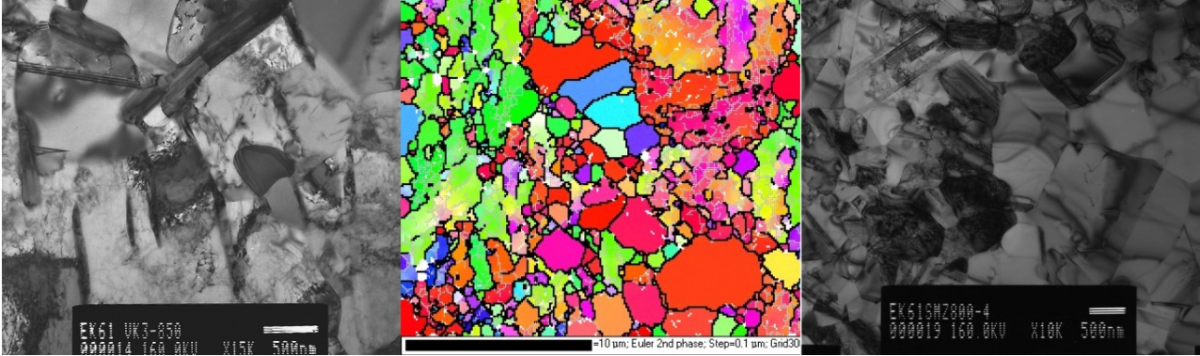

Group of electron microscopic researches

The group of electron microscopic researches solves the problems of analytical and quantitative microscopy, local elemental analysis, crystallographic analysis in microregions. It has two transmission electron microscopes JEM-2000EX from JEOL (Japan), scanning electron microscopes JSM-840A and JXA-6400. These microscopes are equipped with an X-ray dispersive and wave spectrometer for bulk samples (SERIES II by Noran) and thin foils (INKA ENERGY TEM 200 by Oxfords Instruments), a system for analyzing the crystallographic structure of bulk polycrystalline samples by the method of electron backscattering (EBSD) (INKA CRYSTAL 300 from Oxfords Instruments).